Novel biomaterials using Cross Fiber Spinning Technology

Non-woven biodegradable or biostable materials in the nano-micro range are generally fabricated using Electrospinning, a manufacturing technique that requires applying a high voltage.

Problem: Fabrication techniques based on electrospinning provide insufficient control of material homogeneity and reproducibility due to, for instance, poor process stability. In particular when small fibers, such as nanosize fibers, are produced the total yield of the electrospinning process is very low and process scale-up cannot be easily achieved. Other limitations include the spaghetti-like structure of the produced materials resulting in poor mechanical properties due to insufficient fiber interconnection and impactation.

Solution:

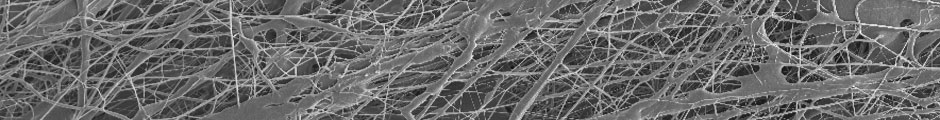

ioos’ CFS Cross Fiber Spinning technology addresses the drawbacks of conventional non-woven fibrous material engineering methods. Novel fibrous materials are constructed of comparatively short polymeric fibers with improved mechanical strength due to a high fiber interconnection. This novel technique allows for the fabrication of various products having a variety of geometries.

Application example: Stent covered with CFS membrane in-between struts