A new quality procedure and metrics has been developed to facilitate the detection of quality problems in various applications including medical device coating, spray drying, mass spectrometry, inhalation (drug delivery), heat transfer, and combustion.

Spray Error Patternation overview

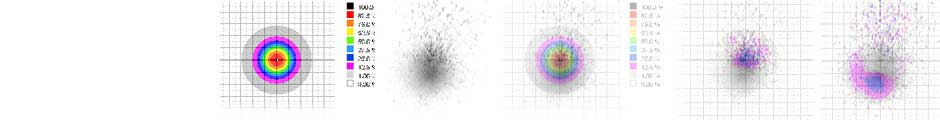

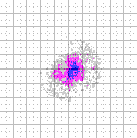

The novel “Spray Error Patternation” method provides quantitative data on the spatially resolved deviations from a reference pattern , referred to as “Spray Patternation (SEP)”. The patented spray characterization method facilitates the evaluation of data relating, among others, to spray surface area, spray density distribution, and/or mass distribution by visualizing deviations or spray errors with respect to an ideal distribution in a two-dimensional plane.

|

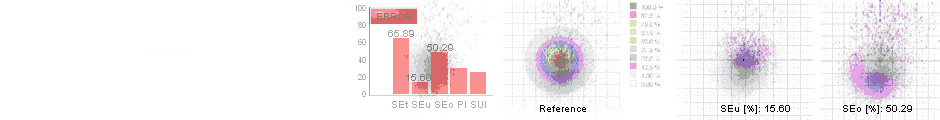

Information on surface area, position, and size of all detected spray errors within the spray to be analyzed is provided and can be quantified and classified as follows: Spray Error total SEtexpresses errors caused by spray under-representation and over-representation. |

|

Spray Error under-representation SEuis a measure for spray under-representations (e.g., voids) within a spray density distribution. These errors are calculated and visualized in a 2D-intensity plot. |

|

Spray Error over-representation SEois a measure for a spray over-representation (excessive spray surface area) within a spray density distribution. These errors are calculated and visualized in a 2D- intensity plot. |

|

|

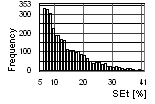

Spray Error frequencyexpresses the number of spray errors within the spray pattern. The error frequency is calculated for SEo, SEu, and SEt and displayed in a histogram. Spray Error eomax and eumaxexpress the maximum error value for SEo, SEu, and SEt , respectively. Error Index E.I.facilitates the assessment of spray errors caused by spray under- and over-representations. |